DAP LOW RECYCLE

Overview

PROCESS FEATURES

The Neutralization of Phosphoric Acid to DAP is achieved in one step in a Single Pipe Reactor.

The granulator has no other internal than the pipe reactor.

Low Recycle Ratio (3.0 compared to5 to 6).

High Solubility of P205 in water (98% versus 90-92%)

EASY OPERATION (only one ammonia current feed to the plant, less equipment required, no need for pumping hot slurries; no need of ammonia sparger inside the granulator, etc.).

The neutralization of phosphoric acid in the pipe reactor can reach N/P ratios as high as 2.0, avoiding then the need of ammonia spargers inside the granulator.

Lower Operation Cost (as consequence of above advantages).

Also, a wide range of NPK Fertilizers can be produced in the same plant.

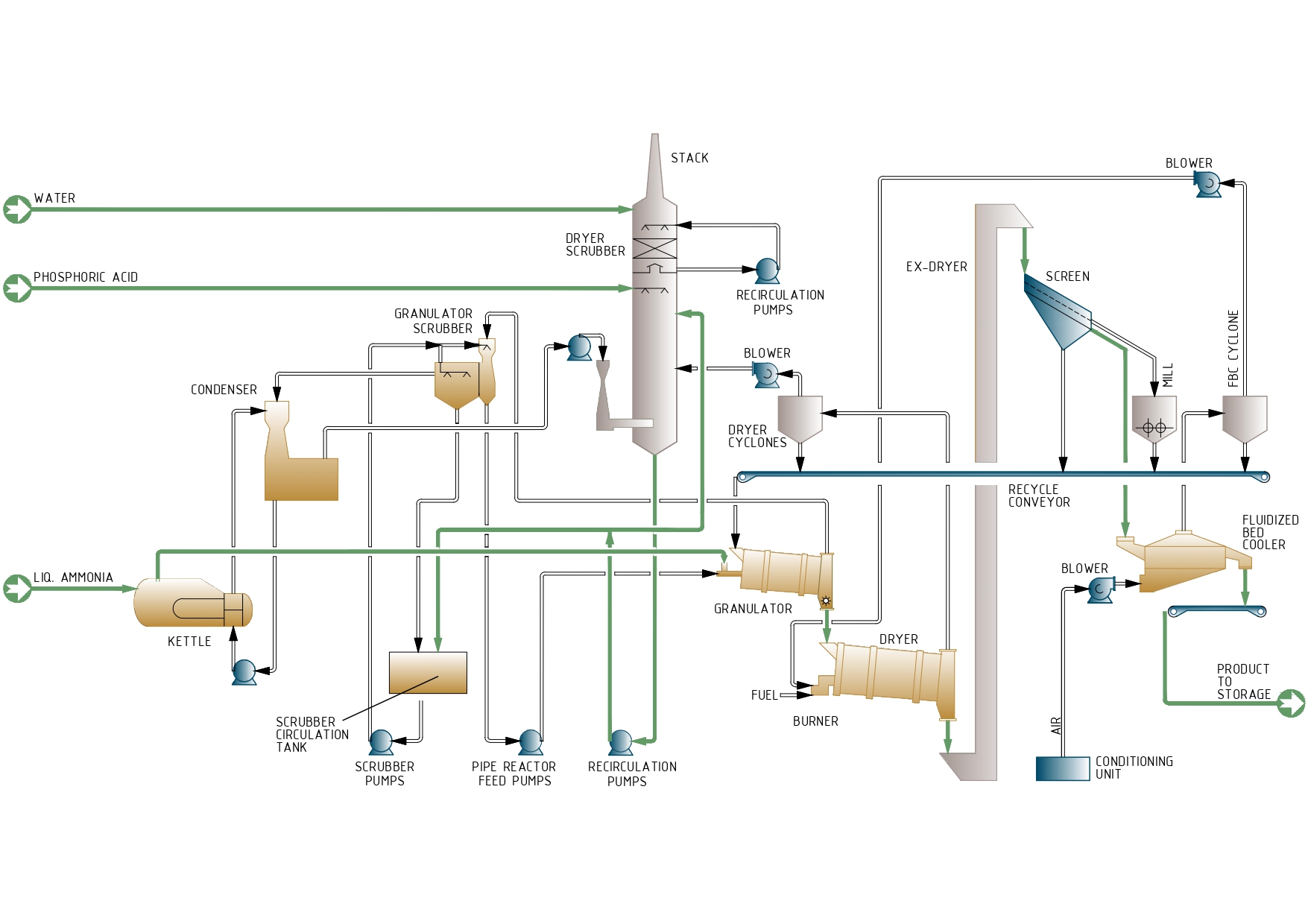

Process Description

Acid Preparation Section

Fresh phosphoric acid is sent to Scrubber System. In the Granulator Scrubber the acid fixes most of ammonia lost from the Granulator. The scrubber liquor results partially neutralized and falls by gravity into the Scrubber Circulation Tank.

In the Drier Scrubber the acid fixes the ammonia evolved in the Drier and also disolves the dust of DAP entrained from the Drier Cyclones. The acid is pumped to the Scrubber Circulation Tank where it is mixed with the acid coming from the Granulator Scrubber.

Pipe reaction and granulation

From the Scrubber Circulation Tank, the partially neutralized Phosphoric Acid enters the Pipe Reactor where the acid reacts with ammonia under pressure to a final molar ratio of 2.0 No need for further ammonia addition in the Granulator bed is required.

The reactions involved are:

NH3+H3PO4 ——————— NH4 H2 PO4 (MAP)

NH3+NH4H2PO4 ————– (NH4)2 HPO4 (DAP)

These reactions are instantaneous and exothermic and the reaction heat is used to evaporate part of the water of the phosphoric acid fed to the Plant. This water vapour and the unreacted ammonia are sucked to air flowing through the Granulator and are sent to Granulator Scrubber.

The DAP melt produced in the reactor is sprayed over the bed of recycle and by temperature effect and moisture it becomes granulated.

To prevent the build up of solids the Granulator walls are lined with selfcleaning rubber panels that also minimize heat losses.

Solid handling

The granulated DAP falls into the rotary Drier where it dries in contact with a co-current flow of hot air coming from the Drier Burner.

Product leaving the Drier is sent, through the Ex-Drier Elevator, to the top of the Screens, where is divided into three streams: the oversize, the on- size and the fines.

The oversize (and some on-size if required) pass into the Oversize Pulverizers. Crushed materials, fines and the dust collected by the Drier Cyclones, FBC Cyclones, and Dedust Cyclones, are discharged on the Recycle Conveyor.

The on-size product from the Screens falls into a Fluidized Bed Cooler where it is cooled to the desired temperature. Finally, the product is sent to the storage.

OPERATING REQUIREMENTS FOR 18-46-0 GRADE DAP

Raw materials Consumption (per metric ton of DAP)

Ammonia (as 100% NH3) 221 kg Phosphoric acid (as 100% P2O5) 463 kg

Utilities Consumption (per metric ton of DAP)

Electricity 35 kWh

Fuel oil 4 kg

Process Flow Diagram