PRILL AMMONIUM NITRATE (LDAN/HDAN)

Overview

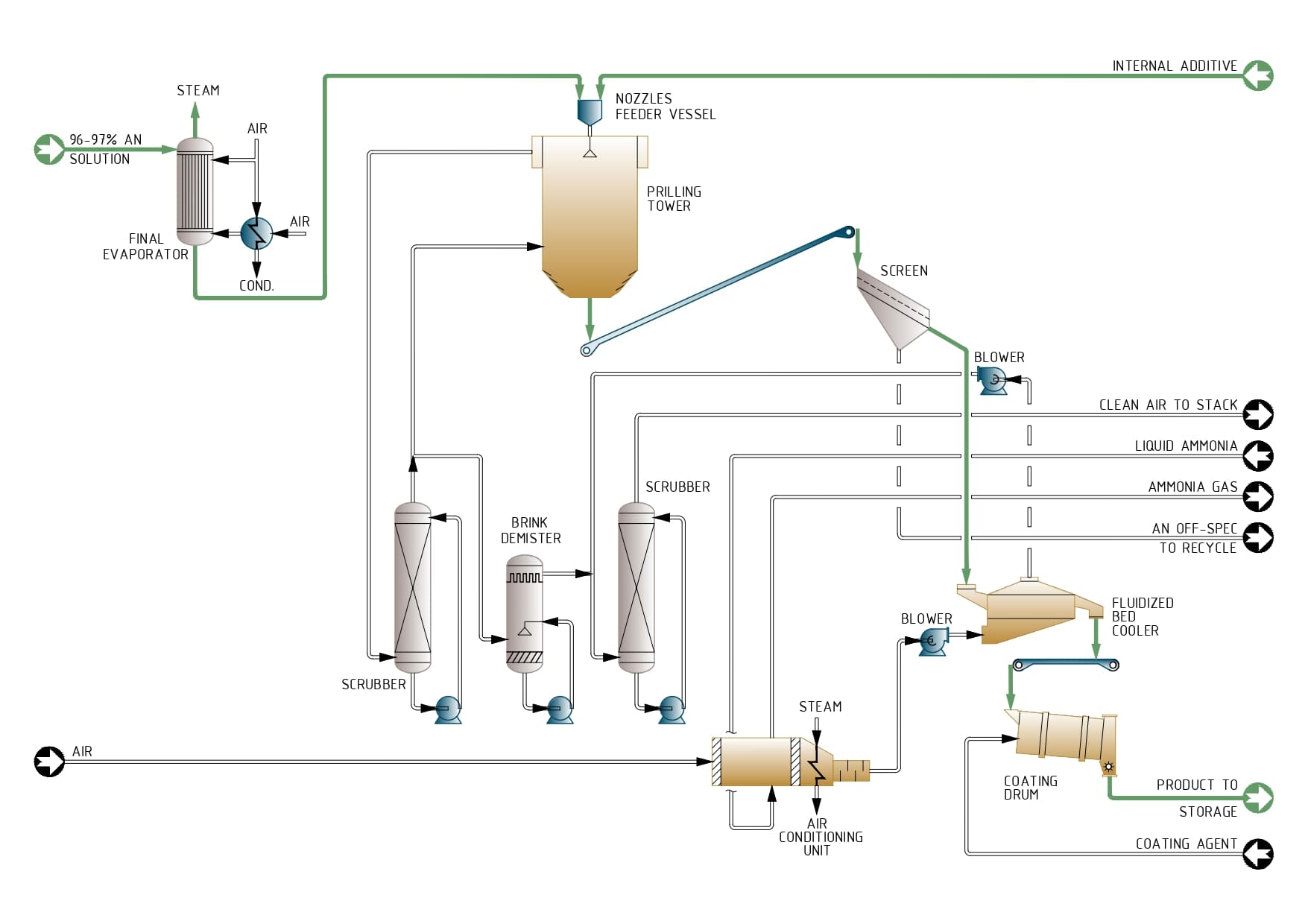

PRILLING PROCESS TO PRODUCE LOW DENSITY AMMONIUM NITRATE

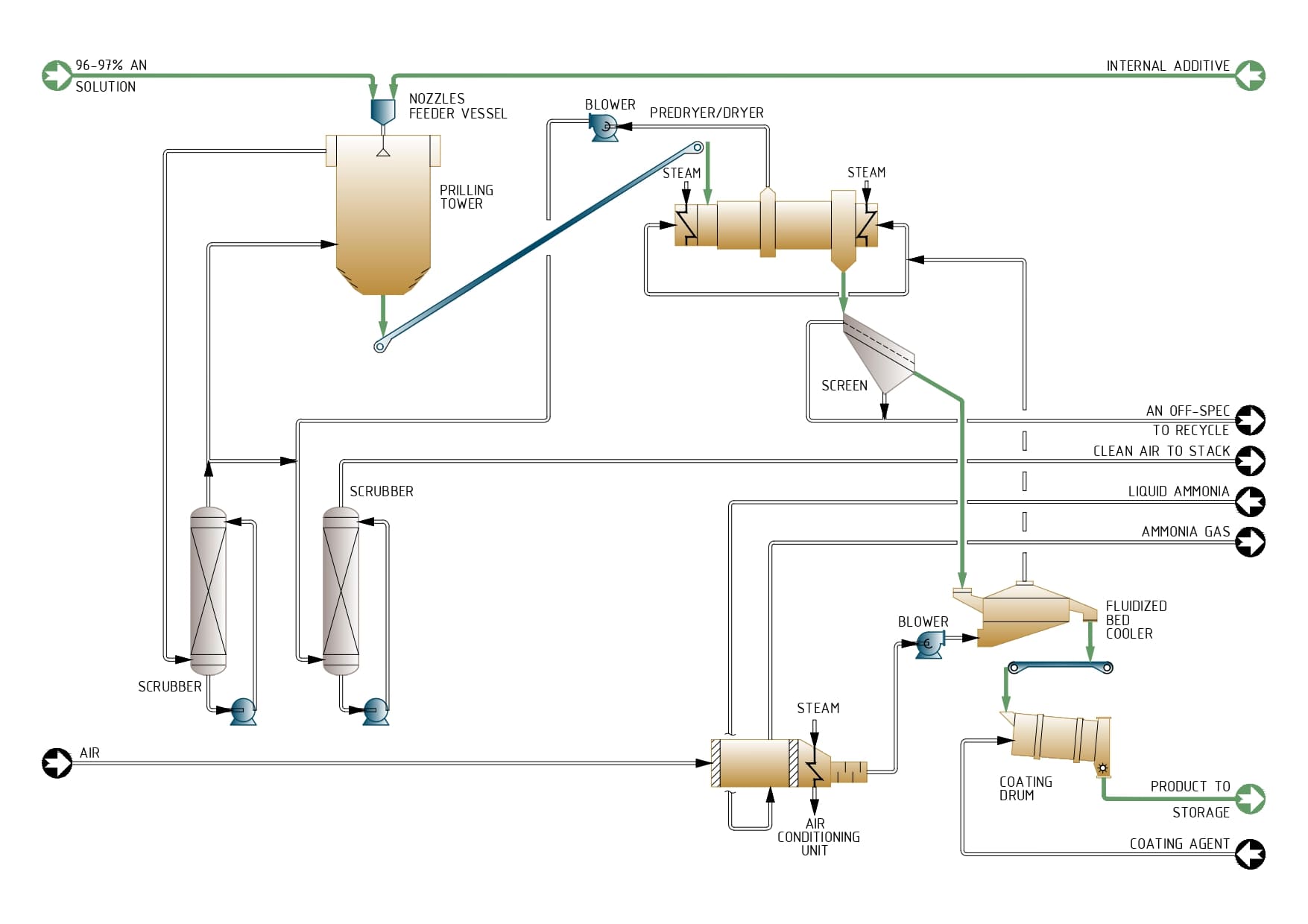

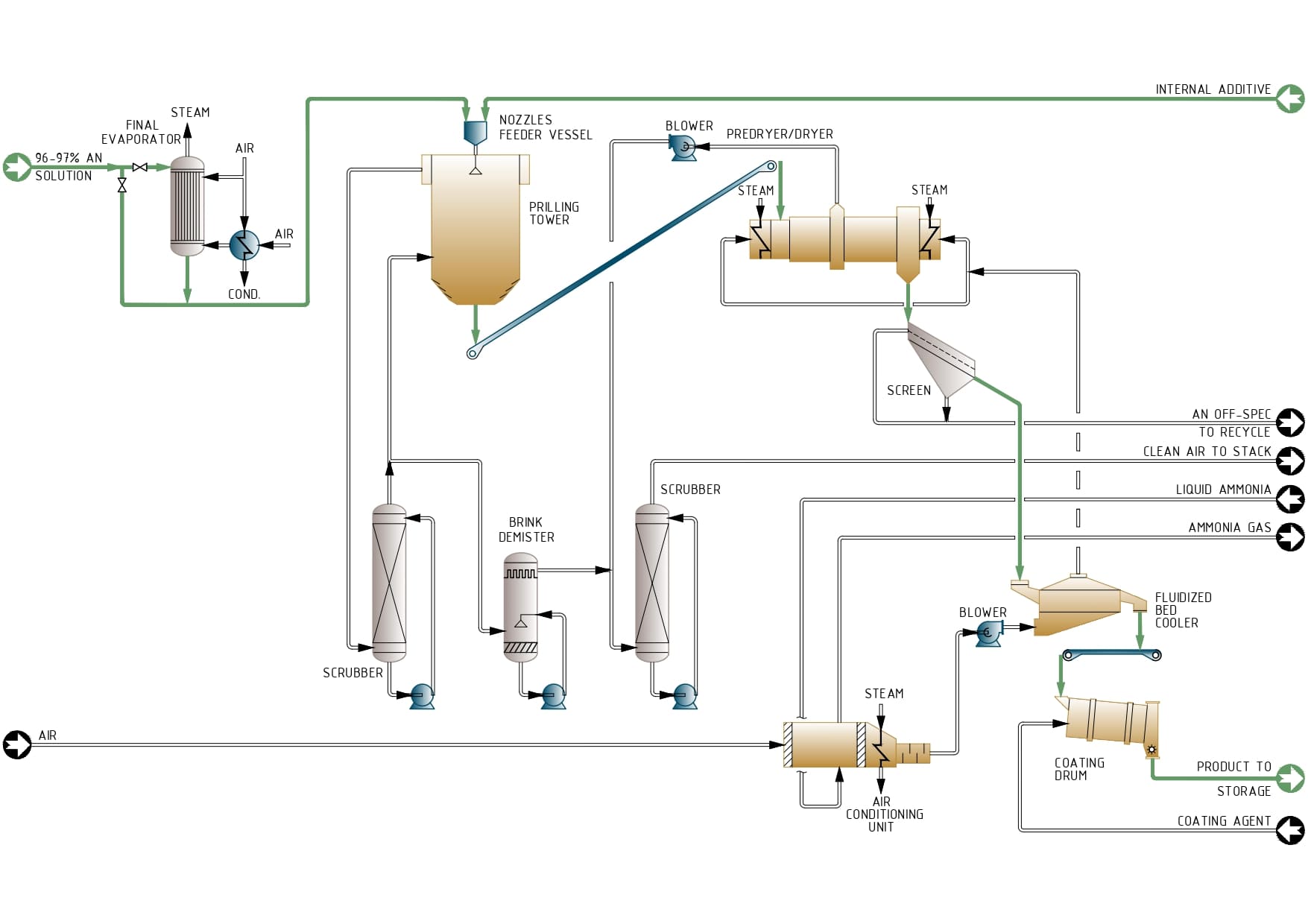

Ammonium Nitrate as described in this brochure, is produced by prilling process to produce Low Density Ammonium Nitrate (base to prepare civil explosives) as well as High Density Ammonium Nitrate (fertilizer grade).

The ESPINDESA process allows using the same plant configu- ration for either low density (LDAN) or high density (HDAN) ammonium nitrate production, by only adding a few pieces of equipment.

The Flexibility is the key advantage of the ESPINDESA process

High quality Low Density Ammonium Nitrate (LDAN) and High Density Ammonium Nitrate (HDAN) can be obtained by means of ESPINDESA processes.

Process Description

96% ammonium nitrate solution obtained in the AN Solution plant is pumped to prilling zone.

(for further information related to the AN Solution preparation, please refer to AN Solution Technology Sheet)

AN Prilling Zone

(for HDAN production, the 96% AN solution is further concentrated in a Final Evaporator located at the top of the Prilling Tower)

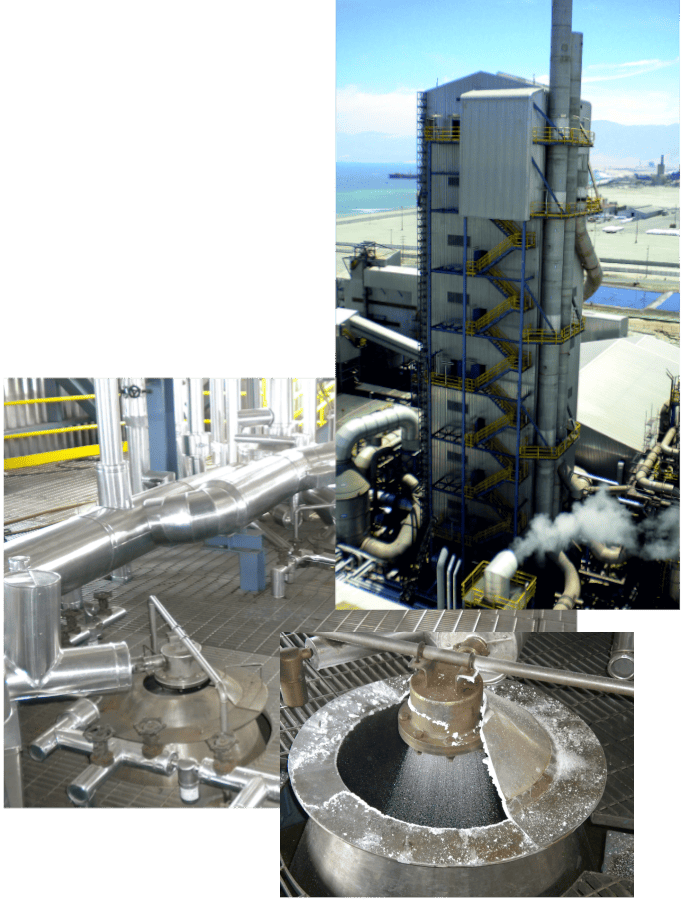

The concentrated AN solution flows by gravity to the Prilling Nozzles, where it is sprayed into the Prilling Tower. Drops of Ammonium Nitrate fall in counter current with air and get solidified while falling.

The air stream leaving the top of the Prilling Tower is scrubbed and cooled in the Prilling Tower Scrubber, which recovers most of the AN contained in the air, and then the air is partially recycled to the Prilling Tower.

The solid Ammonium Nitrate prills are collected at the bottom of the Prilling Tower and sent directly to the drying section.

AN Drying Zone

(For HDAN production, the drying section will be removed, while for joint LDAN/HDAN production, the prills will be dryed/cooled down in the drying drums).

The drying of the prills is done in two steps:

the first one is the pre-drying where heated air flows co-currently to the prills, producing a slow vaporization of most of the water of the prills.

Then the product goes to the second stage, drying section, where heated air flows counter-currently to the solid, allowing a progressive drying which does not damage the prills and gives hardness and porosi- ty to the product.

Dried prills are then sent up to screening.

The air leaving the Predryer and the Dryer drums is sent to the Dryer Air Scrubber Venturi to reduce the emissions prior to be sent to the atmos- phere.

Ammonium Nitrate Screening, Conditioning and Coating zone

The dried product is then classified into three sizes: coarse, on-size and fines. The coarse and fines fractions are recycled back to the process, while the on-size product is cooled in a Fluidized Bed Cooler, which is fed with conditioned air, and the outlet air from FBC is further used in the drying stage.

After cooling, the AN prills are sprayed with a coating agent in the Coating Drum, to prevent product caking during storage and transport.

The AN dust contained in the various air streams is recovered in the final scrubbing system before the air is discharged to the atmosphere, to adjust the gases to the environmental regulations.

Process Flow Diagram